【钜惠】25考研

红包

【专业课】热门类HOT

25考研

【MBA】在职考研

【择校】择专业

计划

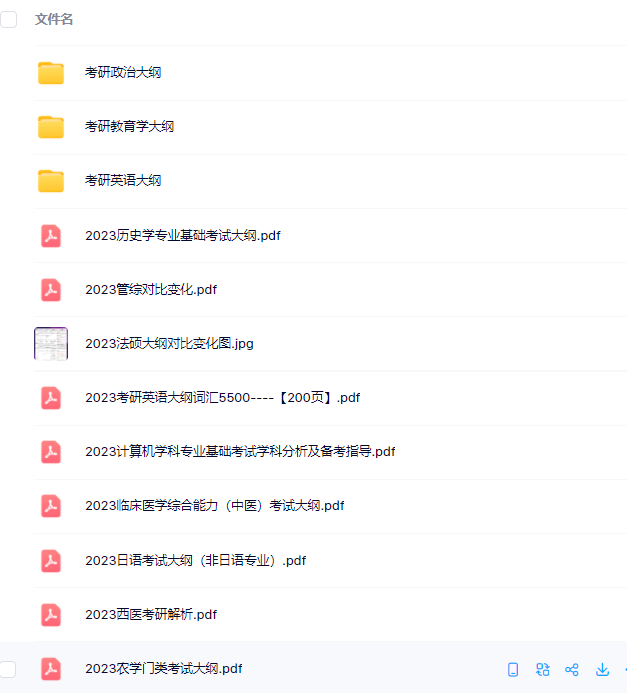

【大纲】电子资料

计划

【25考研】全科学

预备

【在职】择校分析

25考研

【测评】英语|政治

免费

【报录比】查询

免费学

【备考】研友群

精

扫码加入训练营

牢记核心词

学习得礼盒

考研中一般在复试期间大家会联系硕士研究生导师,因为提前联系运气好的话,导师看到你的简历后可能对你非常感兴趣,在不违背原则的前提下没准会对你的复试指点一二。那在和导师邮件沟通的过程中如果你对导师的学术著作颇有研究或者在考研前就已经瞄准某位导师,那就很有必要对于硕士研究生导师的信息提前熟悉了解,方便以后的沟通。下面新东方在线考研频道为大家分享:“中国科学院大学硕士研究生导师信息:白进”文章。

白进 男 硕导 中国科学院山西煤炭化学研究所

电子邮件: stone@sxicc.ac.cn

通信地址: 山西省太原市桃园南路27号

邮政编码: 030001

研究领域煤化学和灰化学:

高温热转化过程中,煤中有机物转化规律及影响因素;

高温热转化过程中,煤中无机矿物质的变迁规律及对有机物转化的影响,飞灰形成机理及颗粒物特性,熔渣流体性质研究,飞灰和灰渣的高附加值利用,煤矸石中矿物质的有效转化;

招生信息2019年招收硕士研究生2名,博士研究生2名,主要从事煤化学、气化过程灰化学和固体废弃物利用的应用基础研究,对学生的要求如下:

1. 勤奋向上、刻苦努力、专注科研;

2. 较好的物理化学基础;

招生专业

081702-化学工艺

085600-材料与化工

081701-化学工程

招生方向

煤化学与灰化学,煤气化

煤气化反应工程

煤基固废利用

科研活动

科研项目

( 1 ) 煤气化熔渣中铁的价态分布对其流动性的影响及机理, 主持, 国家级, 2015-01--2018-12

( 2 ) 精细化智能配煤系统开发与工程示范, 参与, 省级, 2015-01--2018-12

( 3 ) 煤直接液化残渣与低变质烟煤制备气化用水煤浆的基础研究, 参与, 国家级, 2013-01--2016-12

( 4 ) 山西省优秀青年基金项目, 主持, 省级, 2016-06--2018-12

( 5 ) 中科院青年创新促进会优秀会员, 主持, 部委级, 2016-01--2018-12

( 6 ) 高温气化条件下熔渣速度场和黏度的在线测量仪, 主持, 部委级, 2017-01--2019-12

( 7 ) 液态排渣气化炉中灰渣黏度的若干关键问题, 主持, 国家级, 2018-01--2020-12

指导学生已指导学生

黄吉庆 博士研究生 081702-化学工艺

王志刚 博士研究生 081702-化学工艺

孔令学 博士研究生 081702-化学工艺

温海涛 硕士研究生 081701-化学工程

马志斌 博士研究生 081702-化学工艺

张慧荣 博士研究生 081702-化学工艺

代鑫 博士研究生 081702-化学工艺

颜婷珪 博士研究生 081702-化学工艺

陈晓东 博士研究生 081702-化学工艺

贺冲 博士研究生 081702-化学工艺

葛泽峰 博士研究生 081702-化学工艺

曹希 博士研究生 081702-化学工艺

现指导学生

石文举 博士研究生 081701-化学工程

刘梦杰 博士研究生 081702-化学工艺

高龙飞 硕士研究生 081702-化学工艺

黄磊 硕士研究生 081701-化学工程

王冀 博士研究生 081702-化学工艺

袁宗帅 硕士研究生 081702-化学工艺

宋歌 博士研究生 081702-化学工艺

论文[1] Zefeng Ge, Lingxue Kong, Jin Bai*, Xi Cao, Huiling Zhao, Huaizhu Li, Zongqing Bai, Bernd Meyer, Stefan Guhl, Wen Li. Crystallization kinetics and TCV prediction of coal ash slag under slag tapping conditions in an entrained flow gasifier. Fuel, 272, 2020, 117723.

[2] Xiaoming Li#, Lifei Zhi, Wenju Shi*, Lingxue Kong, Jin Bai*, Jianglong Yu, Markus Reinmöller, Stefan Guhl, Bernd Meyer, Wen Li. Effect of K2O/Na2O on fusion behavior of coal ash with high silicon and aluminum level. Fuel. 2020. 265: 116964 (SCI).

[3] Xiaoming Li#, Xiaodong Chen#, Congbin Jiang, Jianping Ding Jinjun Guo, Lingxue Kong, Jin Bai*, Wen Li. Influence of the Slag–Crucible Interaction on Coal Ash Fusion Behavior at High Temperatures. Energy & Fuels. 2020, 34(3):87-3099 (SCI).

[4] Liu, Mengjie; Bai, Jin; Yu, Jianglong; Kong, Lingxue; Bai, Zongqing; Li, Huaizhu; He, Chong; Ge, Zefeng; Cao, Xi; Li, Wen. The correlation between char gasification characteristic at different stages and microstructure of char by combing XRD and Raman. Energy & Fuels. 2020, 34, 4, 4162-4172

[5] Xi Cao, Jin Bai*, et al. Effect of water vapor on viscosity behavior of coal slags with high silicon-aluminum level under gasification condition. Fuel. 2020. 260:116-351.

[6] Wenju Shi, Jin Bai*, et al. Effect of CaO/Fe2O3 ratio on fusibility of coal ashes with high silica and alumina levels and prediction. Fuel. 2020. 260:116-369.

[7] Mengjie Liu, Jin Bai*, et al. The correlation between coal char structure and reactivity at rapid heating condition in TGA and heating stage microscope. Fuel. 2020. 260C: 116-318

[8] Zefeng Ge, Jin Bai*, et al. Effect of CaO/Fe2O3 ratio on slag viscosity behavior under entrained flow gasification conditions. Fuel. Accepted.

[9] Ji Wang, Lingxue Kong, Jin Bai, Huiling Zhao, Stefan Guhl, Huaizhu Li, Zongqing Bai, Bernd Meyer, Wen Li. The role of residual char on ash flow behavior, Part 2: Effect of SiO2/Al2O3 on ash fusibility and carbothermal reaction. Fuel. 2019.225:1-8

[10] Chong He, Jin Bai*, Alexander Ilyushechkin*, et al… Effect of chemical composition on the fusion behaviour of synthetic high-iron coal ash. Fuel. 2019.253: 1465-1472

[11] Tinggui Yan, Jin Bai*, et al. Improved prediction of critical-viscosity temperature by fusion behavior of coal ash. Fuel. 2019.253: 1521-1530

[12] Xiaoming Li, Lifei Zhi, Chong He, Stefan Guhl, Bernd Meyer, Lingxue Kong, Jin Bai, Wen Li. The factors on metallic iron crystallization from slag of direct coal liquefaction residue SiO2-Al2O3-Fe2O3-CaO-MgO-TiO2-Na2O-K2O system in the entrained flow gasification condition. Fuel. 2019. 246:417-424.

[13] Zhigang Wang*. Lingxue Kong, Jin Bai*, Huaizhu Li, Chong He, Ting-gui Yan, …Wen Li. Effect of vanadium and nickel on iron-rich ash fusion characteristics. 2019. 246:491-499.

[14] Chong He. Jin Bai*, et al. Effects of atmosphere on the oxidation state of iron and viscosity behavior of coal ash slag. Fuel. 2019. 243:41-51.

[15] Huirong Zhang, Jin Bai, Wen Li, Fangqing Chen. Carbothermal reactions of tobelite with coal char at high temperatures under N2 atmosphere. Journal of Analytical and Applied Energy. 2019. 137:220-226.

[16] Xin Dai; Jin Bai*; Qing Huang; Zhen Liu; Xiaojing Bai; Ronggen Cao; Xiaodong Wen; Wen Li; Shiyu Du. Viscosity temperature properties from molecular dynamics simulation: the role of calcium oxide, sodium oxide and ferrous oxide. Fuel. 2019.237:163-169

[17] Xi Cao; Lingxue Kong, Dr.; Jin Bai*; Zefeng Ge; Chong He; Huaizhu Li; Zongqing Bai, Prof.; Wen Li. Effect of water vapor on coal ash slag viscosity under gasification condition. Fuel. 2019.237:18-27.

[18] Chong He; Jin Bai*; Weicheng Li; Lingxue Kong; Jiang Xu; Stefan Guhl; Xiaoming Li; Zongqing Bai; Wen Li. Iron transformation behavior in coal ash slag in the entrained flow gasifier and the application for Yanzhou coal. Fuel. 2019.237:851-859

[19] Huirong Zhang, Jin Bai, Wen Li, Fangqing Chen. Comprehensive evaluation of inherent mineral composition and carbon structure parameters on CO2 reactivity of metallurgical coke. Fuel. 2019. 235: 647-657

[20] Zefeng Ge, Lingxue Kong. Jin Bai*….. Effect of CaO/Na2O on slag viscosity behavior under entrained flow gasification conditions. Fuel Processing Technology. 2018.181:352-360

[21] Wen-Ju Shi, Ling-Xue Kong, Jin Bai, Jiang Xu, Wei-ChengLi, Zong-QingBai, WenLi, Effect of CaO/Fe2O3 on fusion behaviors of coal ash at high temperatures. Fuel Processing Technology. 2018. 181: 18-24

[22] Ji Wang, Lingxue Kong, Jin Bai, et al. The role of residual char on ash flow behavior, Part 1: The effect of graphitization degree of residual char on ash fusibility. Fuel. 2018. 234:1173-1180

[23] Daniel Schwitalla, Markus Reinmöller, Clemens Forman, Christian Wolfersdorfa, Matthias Gootza, Jin Bai, Stefan Guhl, Markus Neuroth, Bernd Meyer. Ash and slag properties for co-gasification of sewage sludge and coal: An experimentally validated modeling approach. Fuel Processing Technology 175 (2018) 1–9

[24] Lingxue Kong, Jin Bai, Huaizhu Li, Xiaodong Chen, Zongqing Bai, Wen Li. The mineral evolution during coal washing and its effect on ash fusion characteristics of Shanxi high ash coals. Fuel. 2018. 212:268-273.

[25] Wenju Shi, Xin Dai, Jin Bai, Lingxue Kong, Jiang Xu, Xiaoming Li, Zongqing Bai, Wen Li. A new method of estimating the liquidus temperature of coal ash slag using ash composition. Chemical Engineering Science. 2018. 175:278-285

[26] Xin Dai, Jin Bai, et al. Coal ash fusion properties from molecular dynamics simulation: the role of calcium oxide. Fuel. 2018. 216:760-767.

[27] Xiaodong Chen, Lingxue Kong, Jin Bai, Xin Dai, Huaizhu Li, Zongqing Bai, Wen Li. The key for sodium-rich coal utilization in entrained flow gasifier: The role of sodium on slag viscosity-temperature behavior at high temperatures. Applied Energy. 2017.206:1241-1249.

[28] Xiao-Dong Chen, Lingxue Kong, Jin Bai, Zongqing Bai, Wen Li. Study on fusibility of coal ash rich in sodium and sulfur by synthetic ash under different atmospheres. Fuel. 2017. 202: 175-183

[29] Chong He, Jin Bai, Ling-Xue Kong, Stefan Guhl, Daniel Harry Schwitalla, Jiang Xu, Zong-Qing Bai, Wen Li. The precipitation of metallic iron from coal ash slag in the entrained flow coal gasifier: By thermodynamic calculation. Fuel Processing Technology. 2017:98-104

[30] Tinggui Yan, Jin Bai, Lingxue Kong, Zongqing Bai, Wen Li, Jiang Xu. Effect of SiO2/Al2O3 on fusion behavior of coal ash at high temperature. Fuel 2017,193:275–283

[31] Yan Tinggui, Kong Lingxue, Bai Jin, Bai Zongqing, Li Wen. Thermomechanical analysis of coal ash fusion behavior. Chemical Engineering Science. 2016. 147:74-82

[32] Huirong Zhang, Jin Bai *, Lingxue Kong, et al Thermal transformation of tobelite from coal at high temperatures and the kinetics and mechanism of dehydroxylation and deamination process. Fuel Processing Technology. 2016, 144:203-211

[33] Lingxue Kong, Jin Bai *, Zongqing Bai, Zhenxing Guo, Wen Li. The Internal and External Factor on Coal Ash Slag Viscosity at High Temperatures, Part 3: Effect of calcium on the viscosity-temperature curve. Fuel. 2016, 179:10-16

[34] Xin Dai, Jian He, Jin Bai*, Qing Huang, Xiaodong Wen, Lu Xie, Kan Luo, Jian Zhang, Wen Li, and Shiyu Du. Ash Fusion Properties from Molecular Dynamics Simulation: Role of the Ratio of Silicon and Aluminum. Energy Fuels 2016, 30: 2407−2413

[35] Lingxue Kong, Jin Bai *, Zongqing Bai, Zhenxing Guo, Wen Li. The Internal and External Factor on Coal Ash Slag Viscosity at High Temperatures, Part 1: Effect of cooling rate on slag viscosity, measured continuously. Fuel. 2015, 158: 968-975.

[36] Lingxue Kong, Jin Bai *, Zongqing Bai, Zhenxing Guo, Wen Li. The Internal and External Factor on Coal Ash Slag Viscosity at High Temperatures, Part 2: Effect of residual carbon. Fuel. 2015, 158: 976-982.

[37] Huirong Zhang, Jin Bai *, Lingxue Kong, et al Behavior of Minerals in Typical Shanxi Coking Coal during Pyrolysis. Energy & Fuels 2015 29 (11), 6912-6919.

[38] Zhu Liu, Dabo Guan, Wei Wei, Steven J. Davis, Philippe Ciais, Jin Bai. et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature. 2015, 524: 335–338

[39] Zhibin Ma, Jin Bai *, Wen Li, Zongqing Bai, Lingxue Kong Mineral Transformation in Char and Its Effect on Coal Char Gasification Reactivity at High Temperatures, Part 2: Char Gasification. Energy&Fuels, 2014, 28 (3) : 1846–1853

[40] Zhibin Ma, Jin Bai *, Wen Li, Zongqing Bai, Lingxue Kong Mineral Transformation in Char and Its Effect on Coal Char Gasification Reactivity at High Temperatures, Part 3: Carbon Thermal Reaction. Energy&Fuels, 2014, 28 (5) : 3066–3073

[41] Zhigang Wang, Jin Bai *, Lingxue Kong, Xiaodong Wen, Xiaoming Li , Zongqing Bai, Wen Li, Yue Shi. Viscosity of coal ash slag containing vanadium and nickel. Fuel Processing Technology. 2014, 136:25–33.

[42] Lingxue Kong, Jin Bai *, Zongqing Bai, Zhenxing Guo, Wen Li. Improvement of Ash Flow Properties of Low-rank Coal for Entrained Flow Gasifier. Fuel. 2014, 120 (11-12) : 122-129

[43] Lingxue Kong, Jin Bai *, Wen Li, Zongqing Bai. Effect of CaCO3 on slag flow properties at high temperatures. Fuel.2013, 109(1-2):76-85

[44] Zhigang Wang, Jin Bai *, Lingxue Kong, Wen Li, Zongqing Bai. Effect of V and Ni on Ash Fusion Temperatures. Energy&Fuels. 2013, 27(12): 7303-7313.

[45] Zhibin Ma, Jin Bai *, Wen Li, Zongqing Bai, Lingxue Kong Mineral Transformation in Char and Its Effect on Coal Char Gasification Reactivity at High Temperatures, Part 1: Mineral Transformation in Char. Energy & Fuels, 2013, 27 (8) : 4545–4554

[46] Jin Bai, Wen Li, Baoqing Li. Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere. Fuel, 2008, 87(4-5): 583–591

[47] Jin Bai, Wen Li, Chun-Zhu Li, Baoqing Li. Influences of minerals transformation on the reactivity of high temperature char gasification. Fuel Processing Technology, 2010,91(4): 404-409

[48] Jin Bai, Wen Li, Zongqing Bai. Effects of Mineral Matter and Coal Blending on Gasification. Energy & Fuels,2011,25(3):1127-1131

[49] Jin Bai, Wen Li, Chun-Zhu Li, Baoqing Li. Influences of mineral matter on high temperature char gasification. Journal of Fuel Chemistry and Technology, 2009, 37(2): 134-139

[50] Jin Bai, Wen Li, Chun-Zhu Li, Baoqing Li. Influence of coal blending on mineral transformation at high temperatures. Mining Science and Technology (China), 2009, 19(3): 300-305

[51] Lingxue Kong, Jin Bai *, Wen Li, Zongqing Bai. Effect of lime on slag fluidity of coal ash. Journal of Fuel Chemistry and Technology, 2011, 39(6): 407-412

[52] 温海涛,孔令学,白进,白宗庆,吕冬梅,李文. 高温气化条件下煤直接液化残渣中矿物质演化行为的研究. 燃料化学学报. 2015, 43(3): 257-265.

[53] 孔令学,白进,李怀柱,郭振兴,白宗庆,李文. 利用热机械分析仪测定煤灰熔融性的研究. 煤质技术. 2015, (3): 23-27

[54] 白进,李文,孔令学, 颜婷圭,李怀柱,郭振兴. 气化过程的灰化学及其应用. 煤炭加工与综合利用. 2015, (2): 10-17

[55] 白进, 孔令学, 李怀柱, 郭振兴, 白宗庆, 尉迟唯, 李文. 山西典型无烟煤灰流动性的调控. 燃料化学学报. 2013,41 (07): 805-813

[56] 陈晓东, 孔令学, 白进, 白宗庆, & 李文. (2016). 高温气化条件下na2o对煤灰中矿物质演化行为的影响. 燃料化学学报, 2016. 44(3), 263-272.

[57] 李怀柱, 孔令学, 白进, 白宗庆, & 李文. (2017). 山西"两高"煤灰分对石灰石助熔机制影响的研究. 燃料化学学报, 2017. 45(12), 1409-1416.

[58] 王志刚, 白进, 孔令学, 李怀柱, 白宗庆, & 李文. (2017). Regulation of high temperature flow properties of ash containing v and ni%含v和ni灰高温流动性的调控研究. 燃料化学学报, 045(010), 1164-1171.

[59] 代鑫, 白进, 李东涛, et al. Al2O3-SiO2-CaO-FeO四元体系煤灰结构及流动性关系的实验和理论研究.Experimental and theoretical investigation on relationship between structures of coal ash and its fusibility for Al2O3-SiO2-CaO-FeO system[J]. 燃料化学学报, 2019, 047(006):641-648.

[60] 颜婷珪,白进,孔令学,等.煤灰流动性研究方法进展[J].洁净煤技术,2020,26(1):90-98.

以上就是新东方在线考研频道为大家分享的文章:“中国科学院大学硕士研究生导师信息:白进”。建议大家给导师发邮件题目直接写“姓名 xxx专业硕士自荐信”等,让硕士研究生导师一眼就能知道你的目的。内容主要分成两个部分:第一,要说明自己的情况。第二,要表明对老师研究方向的兴趣。

本文关键字: 硕士研究生导师

资料下载

资料下载

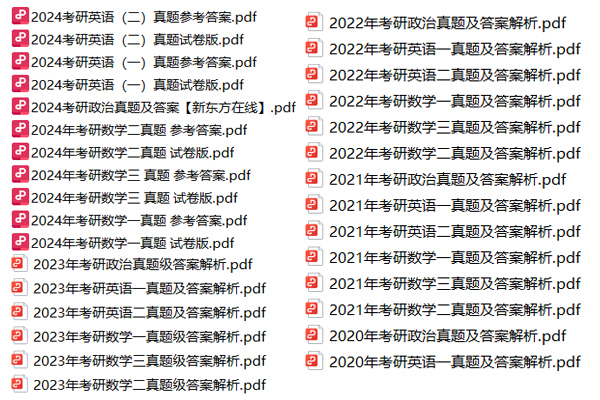

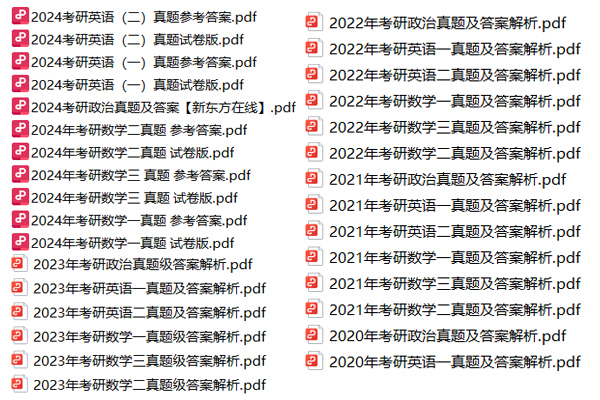

2014年-2024年考研历年真题汇总

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

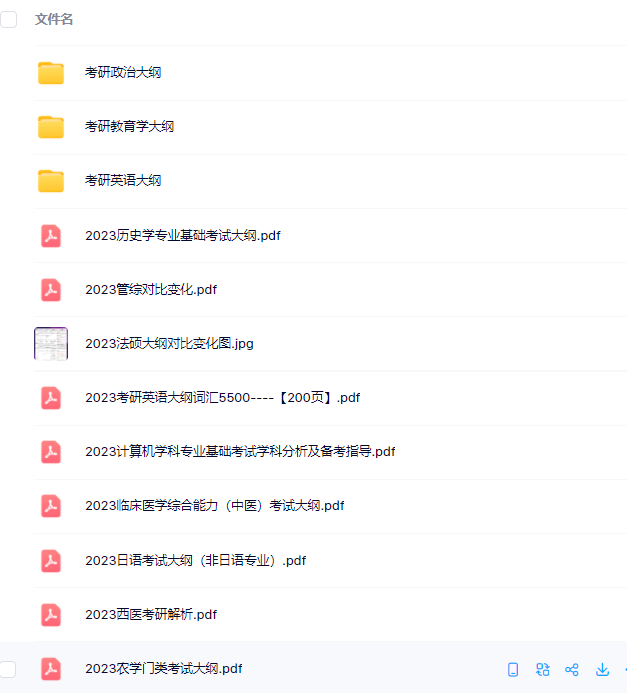

考研大纲PDF电子版下载-历年(附解析)

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

2025年考研政数英备考资料zip压缩包

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

考研英语大纲词汇5500打印版(基础必备)

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

新东方在线考试模拟题【12套】

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

2025年考研专业课知识点总结

发布时间:2024-04-25扫码添加【考研班主任】

即可领取资料包

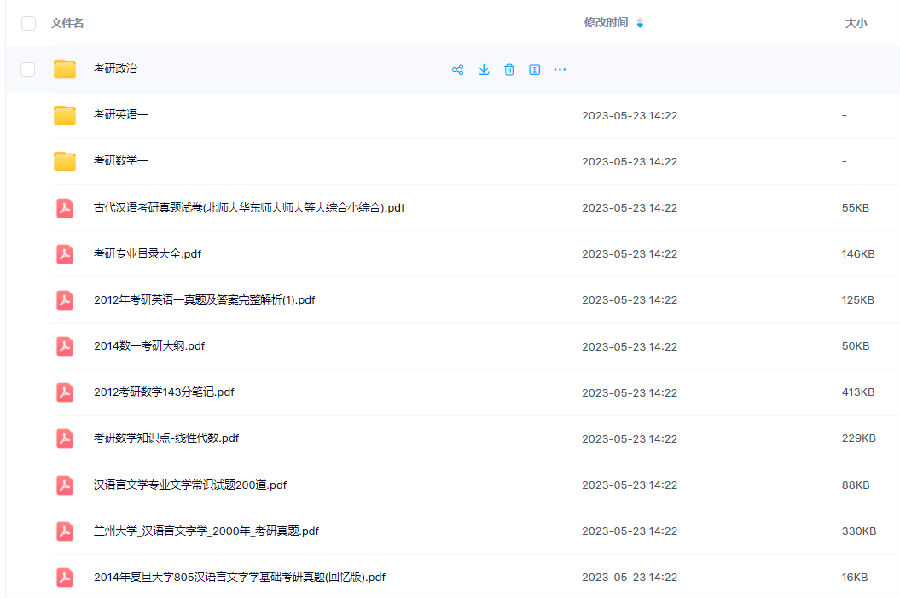

新东方考研资料下载地址

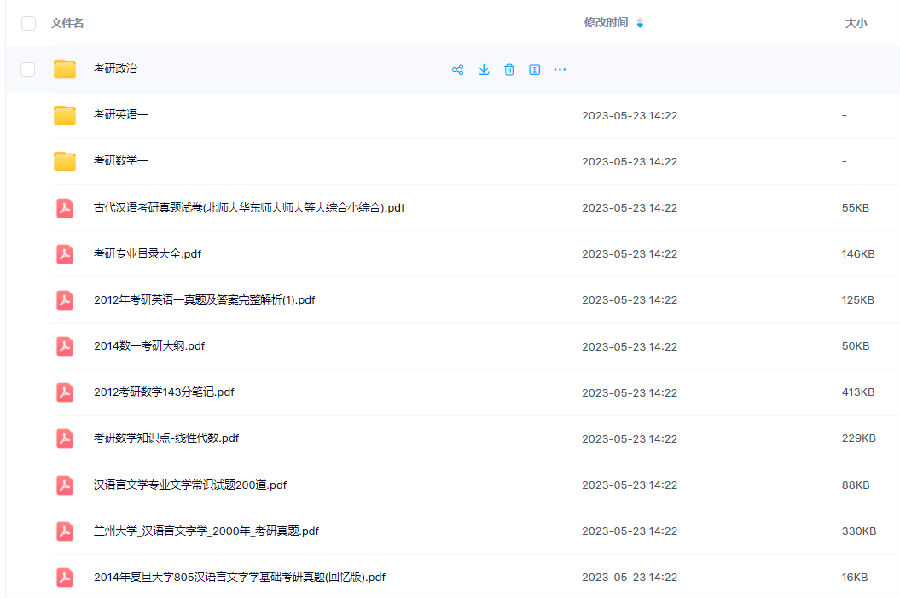

发布时间:2023-05-17新东方在线考研资料合集

下载方式:微信扫码,获取网盘链接

目录:

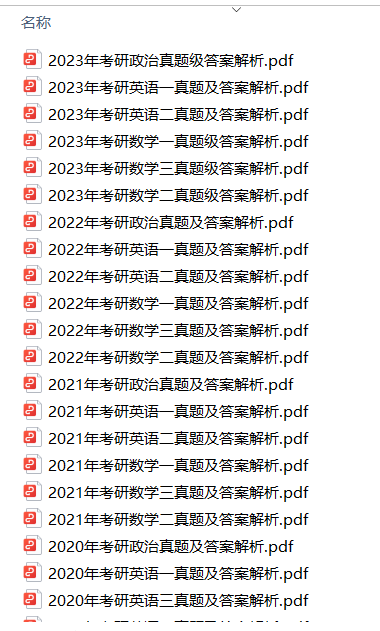

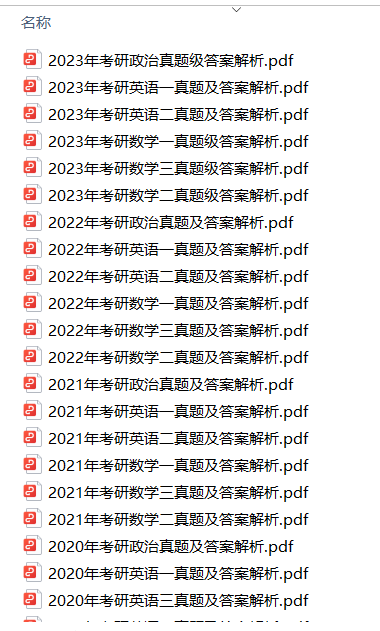

1.2013-2023年近10年政数英真题及解析PDF版(新东方)

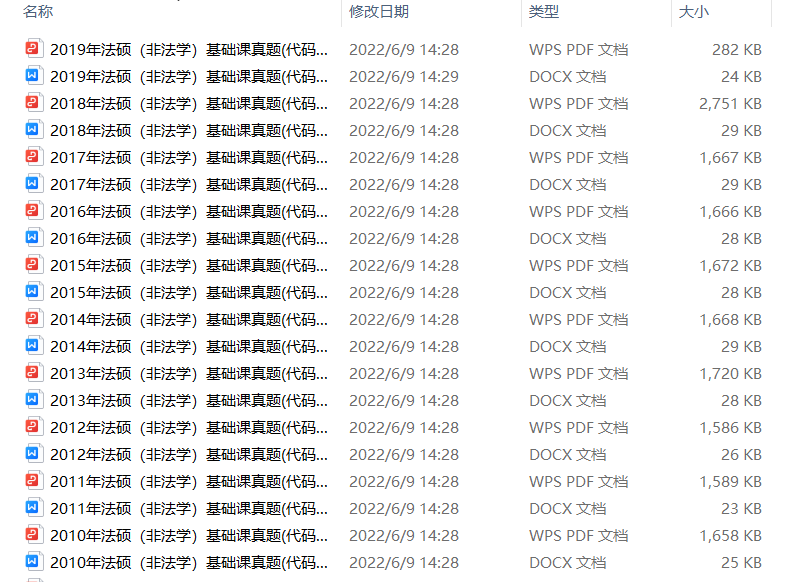

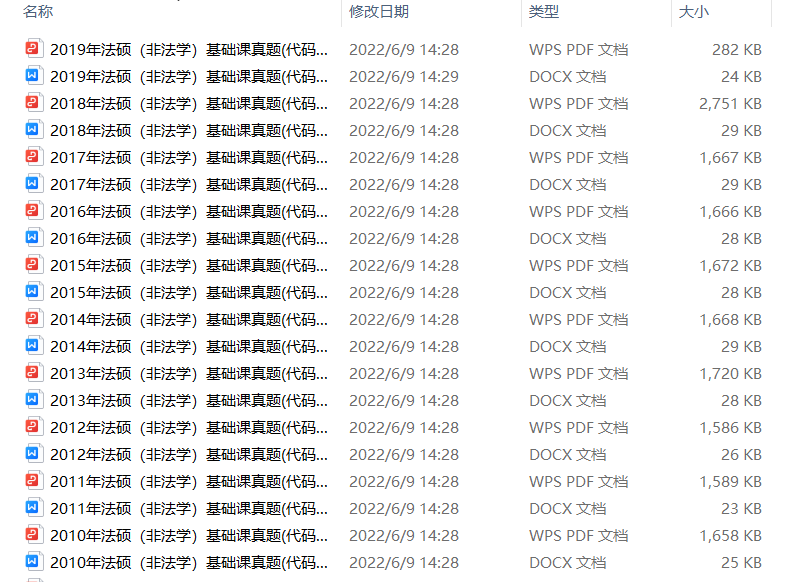

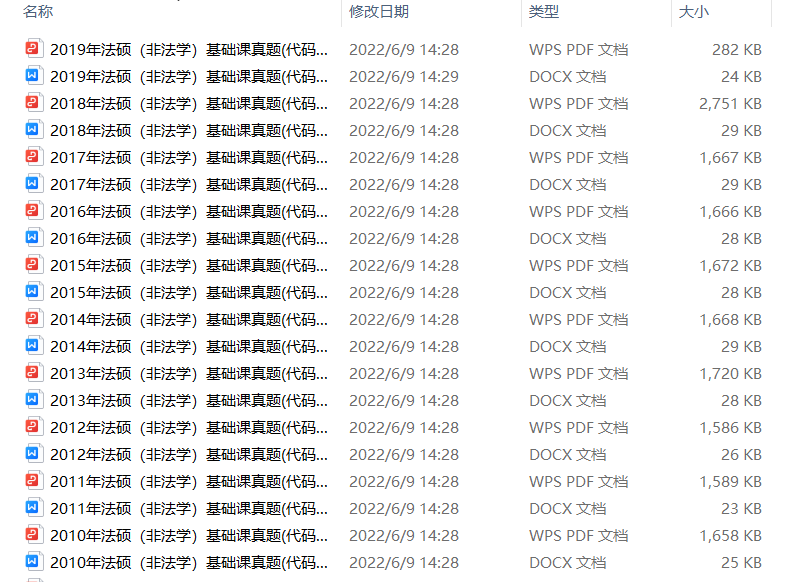

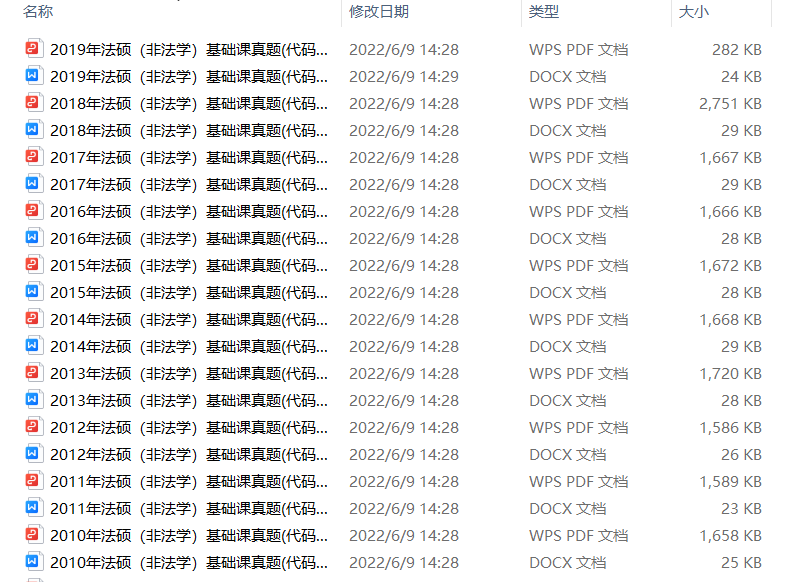

2.2013-2023年专业课考试历年真题及解析PDF版

3.24考研复习备考资料大合集:大纲+备考资料+词汇书+考前押题+自命题

资料介绍:

1.2013-2023年近10年政数英真题及解析PDF版(新东方)

、

、

2.2013-2023年专业课考试历年真题及解析PDF版

3.24考研复习备考资料大合集

3.24考研复习备考资料:考研大纲

3.24考研复习备考资料:政数英备考资料+自命题真题

------------------

考研备考过程中,尤其是专业课部分,参考往年的考试真题,对于我们的复习有更好的帮助。北京大学考研真题资料都有哪些?小编为大家进行了汇总。

北京大学考研真题资料-公共课

北京大学考研真题资料-专业课

以上就是关于“北京大学考研真题资料下载(历年汇总)”的整理,更多考研资料下载,请关注微信获取下载地址。

2024考研公共课必背知识点汇总

发布时间:2023-01-03扫码添加【考研班主任】

即可领取资料包

2013-2023考研历年真题汇总

发布时间:2023-01-03扫码添加【考研班主任】

即可领取资料包

考研英语大纲词汇(PDF可打印)

发布时间:2023-01-03扫码添加【考研班主任】

即可领取资料包

2024考研专业课知识点总结

发布时间:2023-01-03扫码添加【考研班主任】

即可领取资料包

2023考研政治 内部押题 PDF

发布时间:2022-11-16扫码添加【考研班主任】

即可领取资料包

徐涛:23考研预测六套卷

发布时间:2022-11-16扫码添加【考研班主任】

即可领取资料包

考研政数英冲刺资料最新整理

发布时间:2022-11-16扫码添加【考研班主任】

即可领取资料包

23考研答题卡模板打印版

发布时间:2022-11-16扫码添加【考研班主任】

即可领取资料包

2023考研大纲词汇5500PDF电子版

发布时间:2022-07-28扫码添加【考研班主任】

即可领取资料包

考研历年真题(公共课+专业课)

发布时间:2022-07-28扫码添加【考研班主任】

即可领取资料包

考研英语阅读100篇附解析及答案

发布时间:2022-01-07扫码添加【考研班主任】

即可领取资料包

新东方考研学霸笔记整理(打印版)

发布时间:2022-01-07扫码添加【考研班主任】

即可领取资料包

2001-2021年考研英语真题答案(可打印版)

发布时间:2022-01-07扫码添加【考研班主任】

即可领取资料包

考研英语词汇5500(完整版下载)

发布时间:2022-01-07扫码添加【考研班主任】

即可领取资料包

2022考研政审表模板精选10套

发布时间:2022-01-07扫码添加【考研班主任】

即可领取资料包

历年考研真题及答案 下载

发布时间:2021-12-09扫码添加【考研班主任】

即可领取资料包

考研政审表模板汇总

发布时间:2020-06-17扫码添加【考研班主任】

即可领取资料包

近5年考研英语真题汇总

发布时间:2020-06-17扫码添加【考研班主任】

即可领取资料包

考研英语大纲词汇5500

发布时间:2020-06-17扫码添加【考研班主任】

即可领取资料包

2022考研12大学科专业排名汇总

发布时间:2019-11-21扫码添加【考研班主任】

即可领取资料包

2023考研政治复习备考资料【珍藏版】

发布时间:2019-11-21扫码添加【考研班主任】

即可领取资料包

考研英语万能模板+必备词汇+范文

发布时间:2019-11-21扫码添加【考研班主任】

即可领取资料包

考研数学一、二、三历年真题整理

发布时间:2019-11-21扫码添加【考研班主任】

即可领取资料包

添加班主任领资料

添加考研班主任

免费领取考研历年真题等复习干货资料

推荐阅读

推荐阅读

在读研期间,所有与你读研相关的事情,可能都需要经过你的导师同意,所以说,选择导师真的很重要,也希望大家能够认真对待这件事,怎样

来源 : 网络 2022-09-22 07:50:00 关键字 : 硕士研究生导师

在读研期间,所有与你读研相关的事情,可能都需要经过你的导师同意,所以说,选择导师真的很重要,也希望大家能够认真对待这件事,怎样

来源 : 网络 2022-09-22 07:50:00 关键字 : 硕士研究生导师

在读研期间,所有与你读研相关的事情,可能都需要经过你的导师同意,所以说,选择导师真的很重要,也希望大家能够认真对待这件事,怎样

来源 : 网络 2022-09-22 07:50:00 关键字 : 硕士研究生导师

在读研期间,所有与你读研相关的事情,可能都需要经过你的导师同意,所以说,选择导师真的很重要,也希望大家能够认真对待这件事,怎样

来源 : 网络 2022-09-23 07:50:00 关键字 : 硕士研究生导师

在读研期间,所有与你读研相关的事情,可能都需要经过你的导师同意,所以说,选择导师真的很重要,也希望大家能够认真对待这件事,怎样

来源 : 网络 2022-09-23 07:50:00 关键字 : 硕士研究生导师

资料下载

资料下载

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

新东方在线考研资料合集

下载方式:微信扫码,获取网盘链接

目录:

1.2013-2023年近10年政数英真题及解析PDF版(新东方)

2.2013-2023年专业课考试历年真题及解析PDF版

3.24考研复习备考资料大合集:大纲+备考资料+词汇书+考前押题+自命题

资料介绍:

1.2013-2023年近10年政数英真题及解析PDF版(新东方)

、

、

2.2013-2023年专业课考试历年真题及解析PDF版

3.24考研复习备考资料大合集

3.24考研复习备考资料:考研大纲

3.24考研复习备考资料:政数英备考资料+自命题真题

------------------

考研备考过程中,尤其是专业课部分,参考往年的考试真题,对于我们的复习有更好的帮助。北京大学考研真题资料都有哪些?小编为大家进行了汇总。

北京大学考研真题资料-公共课

北京大学考研真题资料-专业课

以上就是关于“北京大学考研真题资料下载(历年汇总)”的整理,更多考研资料下载,请关注微信获取下载地址。

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

扫码添加【考研班主任】

即可领取资料包

阅读排行榜

阅读排行榜

相关内容

相关内容